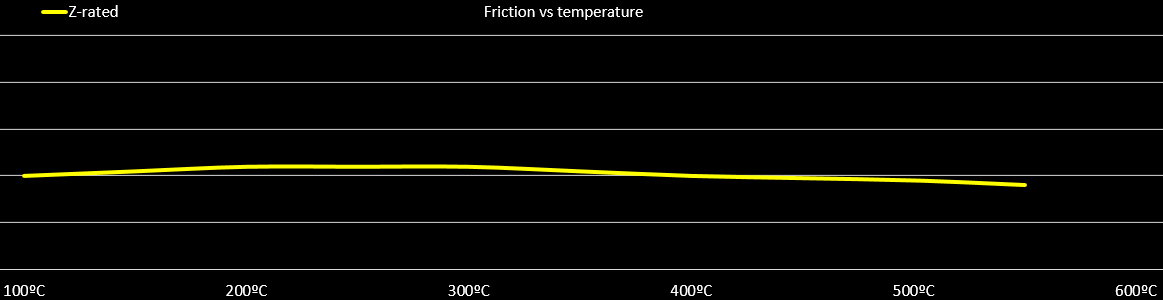

Z-Rated compound has been developed for fast road / track day applications. It provides more stopping power and increased fade resistance over the standard OE materials but retains the good qualities of the road pad i.e., low dusting and noise along with low wear rate.

Z-Rated compound has been developed for fast road / track day applications. It provides more stopping power and increased fade resistance over the standard OE materials but retains the good qualities of the road pad i.e., low dusting and noise along with low wear rate.

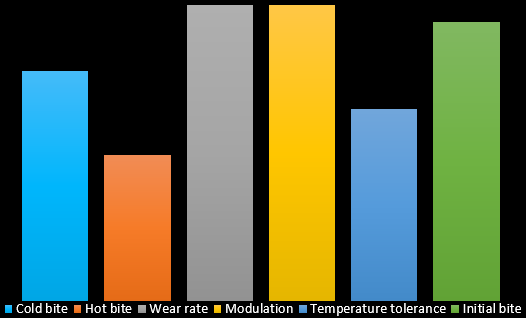

• High performance compound, gained through competition pad developments • Compound designed for low dusting qualities • Several built-in noise suppression technologies • Excellent disc conditioning, giving even transfer layer on disc to reduce uneven pad deposits.

Typical applications: This compound can be used in OE calipers or aftermarket brake kits in applications where an increase in performance is required over the standard OE friction material.

Data PDF

Quieter – Outperforms all ceramic and semi-metallic pads in noise tests resulting in less than 1% noisy stops.

Quicker – CarbonMetallic® pads deliver more stopping power throughout the operating temperature range. Firmer and more responsive pedal.

Lower Dust – CarbonMetallic® brake pads contain ZERO hazardous dust.

Last much longer – CarbonMetallic® brake pads have a higher thermal threshold making them more resistant to wear than any other semi-metallic or ceramic pads during temperature range testing. This results in better brake pad and disc life.

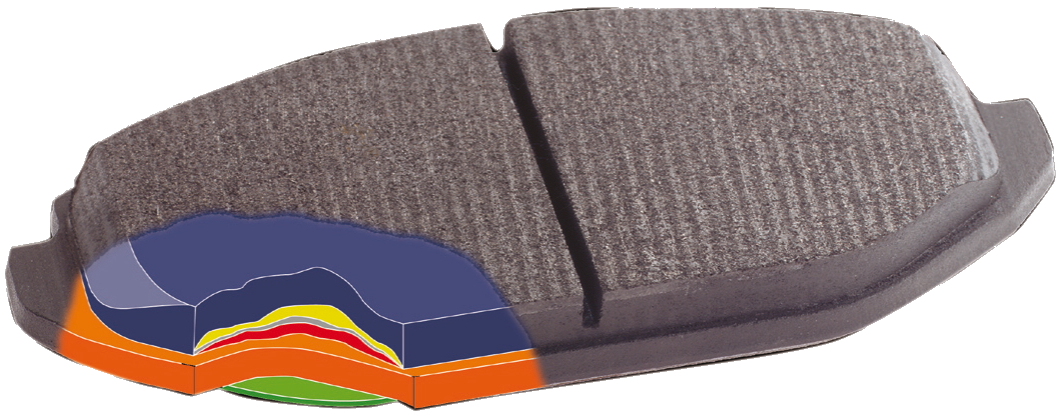

CarbonMetallic® Technology

Multi-Layer Technology™ – Eliminates noise.

FEA Designed Chamfer – Eliminates noise and allows for smoother actuation and a firmer pedal.

FEA Designed Chamfer – Eliminates noise and allows for smoother actuation and a firmer pedal.

IONIC FUSION™ – No pad separation.

Temperature-resistant shims – Final noise barrier. Does not deteriorate with temperature.

Patented powder coating – Reduces corrosion and extends pad life.

Laser Diffraction Technology – Measures raw material particle size to ensure perfectly consistent particle structure & density.