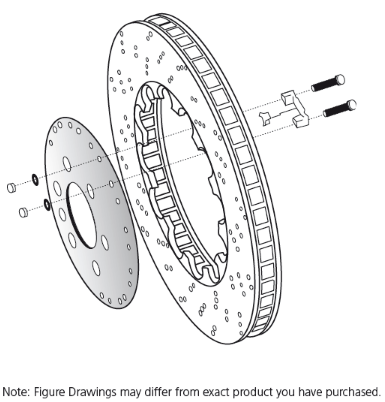

Direct Drive floating disc – assembly steps:

Slide spring clip around the bobbin.

Place hat or hub “upside down” with holes facing upwards.

(Note: for aluminium hats placed laser-etched side facing down)

Place disc on top and line up flanges.

Place assembled bobbin and clip to each flange.

Drop bolts through bobbin assembly. Hand-tighten initially until all bolts are in place. The order you tighten the bolts does not matter.

Note: choose the procedure in this step based on the style of rotor you have purchased. Improper assembly at this step could damage individual components during assembly. Certain iron hats / hubs have threads built in. For those no washer or nut is needed.

Once all bolts are in place, tighten with a torque wrench to 14 Nm per bolt.

** Incorrect setting of this could result in catastrophic brake failure. **