PFC releases Corrosion Resistant Protective Coating

(Clover, SC) January 7, 2012 – PFC Corrosion Resistant Protective Coating is a technology unlike any of the competitors. The coating prevents rust, peeling, corrosion, and is extremely temperature resistant.

The PFC coating incorporates high temperature ceramic technology for strong protection on all surfaces of the brake pad. Under extreme testing procedures, the PFC coating withstands all the elements. PFC put the anti-corrosion coating through extreme testing procedures. Within the industry, it is known as the GM9540P testing procedure and is one of the best testing procedures to predict coating lifetime. PFC has added the 650 oF bakes to simulate environmental conditions usually seen under braking.

PFC Corrosion Resistant Protective Coating also endured a salt spray and high temperature exposure test, resulting in absolutely zero coat peeling and minimal to zero rust, with red rust calculated between only 1 – 2%.

After exposing the coated pads to a second PFC cycle of testing, enduring double the salt spray and high temperature bakes, the PFC pads had minimal rust, with red rust calculated between only 2 – 5%. The coating did not peel from the pad, proving its extreme resistance to the salt spray and high temperature exposure. After a third exposure to the PFC testing cycle, enduring triple the salt spray and high temperature bake, the PFC pads had little rust, between 5 – 15%.

Other competitor protective coatings fail completely, ending in severe peeling, excessive red rust, and even 100% red rust coverage on the brake pads—after only one cycle of testing.

PFC Corrosion Resistant Protective Coating withstands all environmental and extreme driving elements.

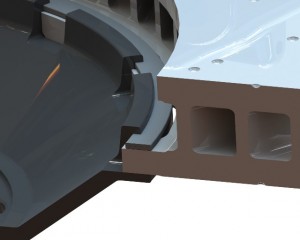

(Clover, SC) – PFC has released new V3 disc and hat technology. The advanced design features a retention ring that holds the hat and disc together.

(Clover, SC) – PFC has released new V3 disc and hat technology. The advanced design features a retention ring that holds the hat and disc together.